Company

The almost 100-year tradition of Max Hauser Süddeutsche Chirurgiemechanik GmbH in the development and manufacture of surgical instruments for human surgery is both obligation and motivation for us.

Today more than ever, we feel obligated to the quality, innovation and sustainability of our instruments.

Our extensive experience in the development and manufacture of surgical instruments combined with the latest findings of modern materials and production technologies are our motivation to make what we have achieved even better.

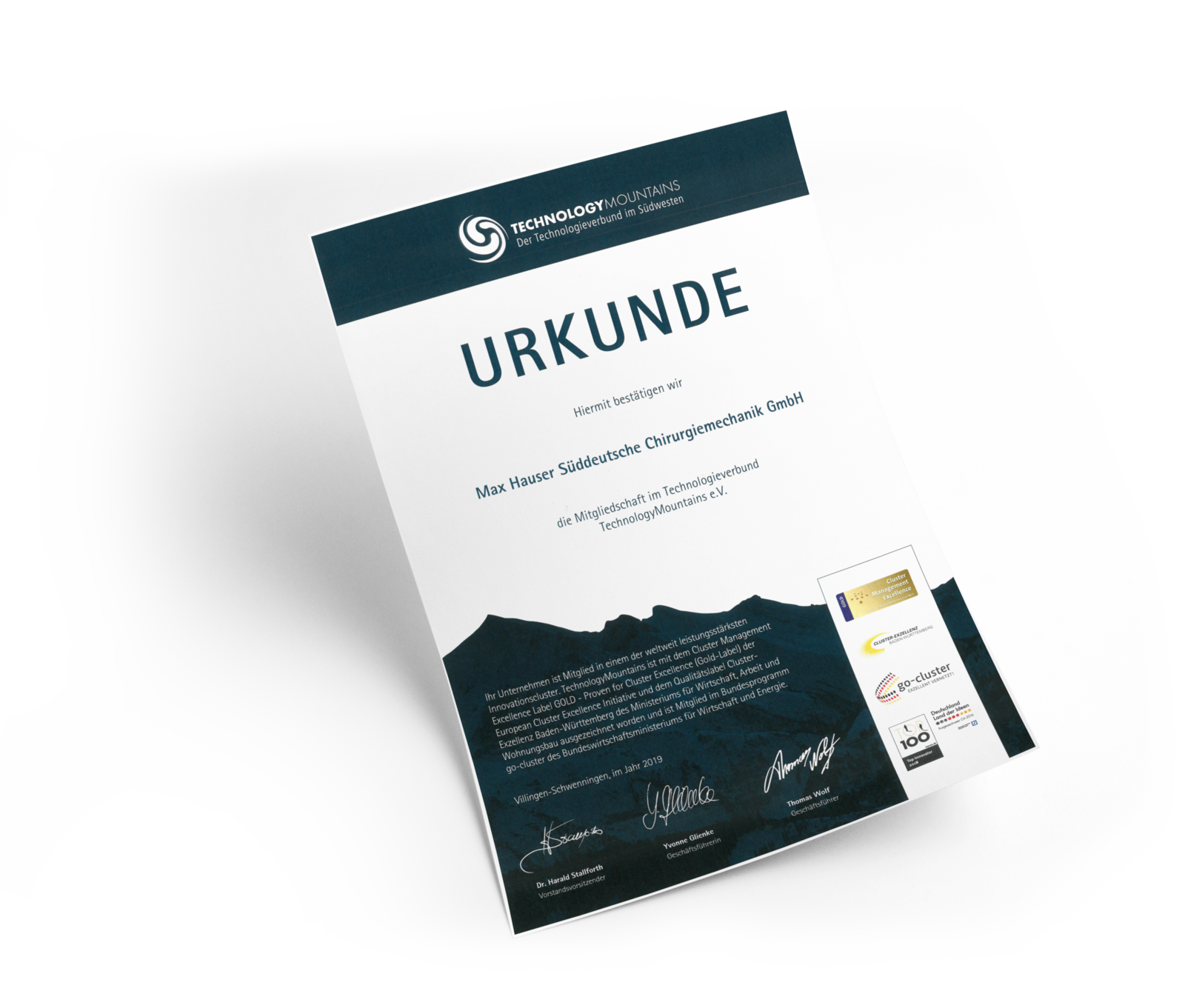

Membership @ Technology Mountains

Technology Mountains is an Innovation Cluster in southwest Germany

The composite counts about 350 company memberships, all based in the county of Baden Württemberg. The Companys from many diffrent industry sectors as for example the car industry, the electric technician, the medical technician, mechanical engeneering and more are the top companys in their subject.

Together the members from Technology Mountains can support each other and their selfs while cooperating with each other by cooperative projects and engeneering for example. Because together we are stronger and making progress gets easier.

Our vision is born of tradition:

Science and technology in the service of people and nature.

Company history

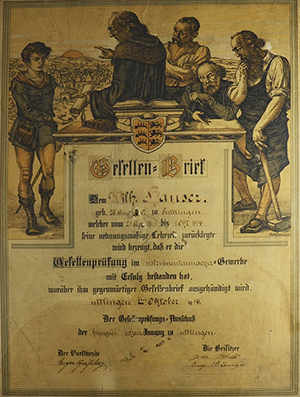

| 1921 | Friedrich Wilhelm and Marie Hauser found in January the "Süddeutsche Chirurgiemechanik GmbH ". The focus is on the production of instruments for thorax and lung surgery. The principle of the company is: ONLY to produce first-class instruments and to offer them to customers. This principle is still our key note today. | |

| 1938 | Friedrich Wilhelm Hauser hands over to his oldest son Max Hauser. Max and Anna Hauser continue the company under the "Max Hauser Süddeutsche Chirurgie Mechanik". | |

|

| |

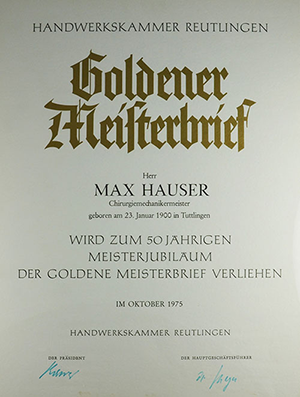

| 1971 | Company celebration for the 50th anniversary of the company. Max Hauser Süddeutsche Chirurgie-Mechanik is well known as sole manufacturer of "aluminum rib retractors" for the heart-lung surgery, also the retractors developed by the famous heart surgeons Doctor Braastadt and Doctor Cooley. The versatile sales program is exported to all countries of the world. | |

1989 | Change to "Max Hauser Süddeutsche Chirurgiemechanik GmbH". | |

| 1990 | The steady growth of the company requires the move to new business and production premises. | |

| 1997 |

| |

| 2001 | The takeover of Hetzel GmbH expands our production portfolio with the product group of “self-retaining retractors”. | |

2005 | Founding of the Hauser Benchmark Factory GmbH & Co. KG in Weißenfels near Leipzig with 1.250m² production area for machining production with modern CNC turning and milling centers as well as wire EDM machines. | |

| 2007 | Certification according to ISO 13485. | |

| 2014 | Moving to larger business and production premises. | |

| 2016 | The first automation project with a flexible handling robot connected to a CNC machining center is successfully launched for serial production. | |

| 2018 |

| |

| 2019 | Another automation project with a flexible grinding robot cell is going into series production. Our new product line for sliding shaft instruments goes into series production. A marking station of the latest generation (ultra-short pulse laser) goes into series production. | |

| 2020 | Introduction of new product brochures. Capacity expansion at Hauser Benchmark Factory GmbH & Co. KG by a milling machining center with automated loading and unloading. | |

| 2021 | Max Hauser Süddeutsche Chirurgiemechanik GmbH celebrates its 100th company anniversary Generation change: Mr. Walter Rehm hands over his company shares to his sons Matthias and Sebastian Rehm | |

| 2022 | Further capacity expansion at Hauser Benchmark Factory GmbH & Co. KG by 2 new milling machining centers. Introduction of the CAM system "SolidCAM“ with „iMachining“ | |

| 2023 | At Hauser Benchmark Factory GmbH & Co. KG puts a 5-axis machining center into operation for the first time in the company history. Max Hauser Süddeutsche Chirurgiemechanik GmbH moves to a energy-efficient company building in Tuttlingen, Im Mittleren Ösch 4. | |

| 2024 | By taking over and integrating the inventory and employees of Johann Deufel GmbH, we are expanding our vertical integration in the production of high-quality clamps. Johann Deufel GmbH in Kolbingen, a family business founded in year 1942, was known for machining high-quality clamps and ring handles of all kinds made of steel, titanium, titanium alloys and plastics. This makes Max Hauser Süddeutsche Chirurgiemechanik GmbH one of a select group of companies in Germany that independently manufacture high-quality clamps from forged materials. Commissioning of a fully automatic wash-out and passivation system and a new circular vibrator and centrifugal vibratory finishing system at Max Hauser Süddeutsche Chirurgiemechanik GmbH |